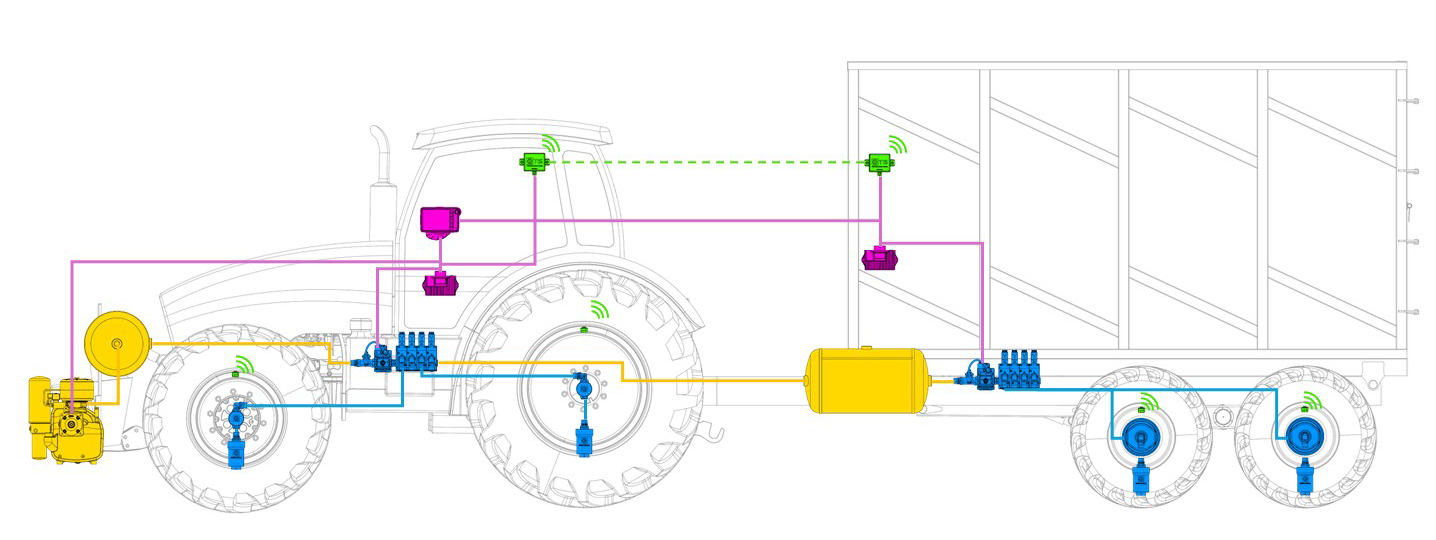

QTIS SYSTEM STRUCTURE

Generation of compressed air: the compressor

To inflate your tyres quickly and minimise downtime in the field, a high-capacity compressed air compressor is recommended. Vane compressors and screw compressors are commonly used for tyre inflation. Due to short compressor cycles, moisture can build up in the oil, potentially impairing compressor performance. It is best to heat up the compressor oil thoroughly at least once every 3 to 5 operating hours by running the compressor for a minimum of 15 minutes, allowing the moisture to evaporate from the oil.

Although there are several options for drying the compressed air (cooling, adsorption and membrane drying), sufficient attention is rarely paid to this. But we all know the consequences of damage caused by moisture in your air system: corrosion, clumped dirt, stuck components due to disturbed lubrication, water hammer, frost damage and more.

A few examples of what one inflation cycle of your tractor with trailer (5000 litres tyre volume and two bar pressure increase) can generate in condensation under different conditions: (see table below)

| Temperature | Grams vapour/ m3 | Temperature | Grams vapour/ m3 |

|---|---|---|---|

| 40 °C | 50.67 | 7 °C | 7.73 |

| 35 °C | 39.29 | 6 °C | 7.25 |

| 30 °C | 30.08 | 5 °C | 6.79 |

| 25 °C | 22.83 | 4 °C | 6.36 |

| 20 °C | 17.15 | 3 °C | 5.95 |

| 15 °C | 12.74 | 2 °C | 5.57 |

| 10 °C | 9.36 | 1 °C | 5.21 |

| 8 °C | 8.24 | 0 °C | 4.87 |

Dry spring day: 20°C, relative humidity 35% and 1m3 of air contains: 0,35%*17,5g/m3= 6.1 grams of water vapour. At 10 bar of compressed air, 11 m3 is compressed with 67.4 grams of compressed water vapour. After cooling to 20°C, 17.5 grams of water vapor will remain in the air and 67.4-17.5 = 49,9 grams of condensate is made by 1000 litres of air at 10 bar.

Humid summer day: 35°C, relative humidity 55% and 1m3 contains 0.55 * 39.29 gr/m3 = 21.61 grams. At 10 bar and after cooling: (11 x 21.61) – 39.29 = 198,41 grams of condensate is made by 1000 litres of air at 10 bar.

Crisp winter's day: 0°C, relative humidity 15% and 1m3 contains 0.15% *4.87 gr/m3= 0.73 grams of water vapour. At 10 bar and after cooling: (11 x 0.73) – 4.87 = 3,16 grams of condensate is made by 1000 litres of air at 10 bar.

Filter and dry compressed air

Although the compressor's intake filter can remove dirt and dust, water vapour from the ambient air is still drawn in and mixed into the compressed air. Since warm air exiting the compressor can hold more water vapour than cold air, the vapour will eventually reach a saturation point (dew point) somewhere in your compressed air system as it cools, at which point it condenses into water. As long as the compressed air continues to cool, it will keep releasing condensate.

This is why cooling air in storage tanks releases condensate. However, when inflating tyres, the warm compressed air flows throughout the system, and without proper measures, condensation can occur almost anywhere. Our advice: cool the compressed air as much as possible and remove the resulting condensate using a cyclone filter and a condensate drain. Optionally, use a large adsorption dryer to further dry the air, ensuring no damage occurs even in freezing conditions.

Reach out for bespoke advice.. Of course, we can also integrate your existing compressor into the optimal control system to provide the best technical solution.

The QTIS tyre pressure control system

We understand that you may not wish to change the compressor on your vehicles after all these years, or that you prefer to use your own ECU to avoid validation procedures. However, the tyre pressure control system is the minimum QTIS solution you can implement. A rim valve is mounted on the wheel and connected via a single Ø16 mm supply line to the rotary union, which is centrally installed on or inside the axle and linked to the valve block. The rim valve maintains tyre pressure while the hose normally remains pressure-free.

When the valve block supplies a pressure of up to 4 bar to the supply line connected to the rim valve, the tyre is inflated. Once the target pressure is reached, the valve block vents the supply line. If you want to deflate the tyre, the control system switches the valve block to a high-pressure mode (> 7 bar), causing the rim valve to shift to a deflation position. The contaminated air from the tyre passes through a fine, large-surface filter inside the rim valve and is vented directly into the atmosphere, preventing contamination of your system’s air supply.

We recommend that your supply line has a minimum internal diameter of Ø12 mm. This ensures that the deflation capacity of our rim valve is the fastest on the market, achieving 0.05 bar/sec with a 900-litre tyre. The smaller the tyre, the faster the deflation.

To reduce tyre inflation times, you can also work with higher inflation pressures — but this requires using higher deflation pressures as well. For this purpose, we recommend adding an extra pressure tank of approximately 20 litres per vehicle.

Please note: inflation times always depend on the compressor capacity, as well as the volume and pressure of the compressed air tanks. For product details and STEP files of the valve block, rotary unions and rim valve, see QTIS PARTS.

We are happy to provide a test installation on your vehicle, offer design support, or prepare a technical proposal for the complete system.

TPMS sensors

We have chosen TPMS (Tyre Pressure Monitoring System) sensors, mounted directly onto the standard TR618A valve in your rim. This method ensures the most reliable pressure measurement. Installation inside the tyre is also possible.

When measuring pressure in flowing air lines, you are dealing with dynamic pressure, which can show significant deviations compared to the static pressure present inside the tyre. Therefore, if you want to set tyre pressures quickly and accurately, we recommend measuring directly inside the tyre. This allows you, for example, to detect leakage or unwanted tyre heating, or to adjust the pressure on one side of the vehicle in sloped conditions.

We have improved the tyre pressure sensor with faster pressure feedback for a more accurate system. The TPMS sensors wirelessly transmit the tyre pressure, temperature, and battery status from each tyre to a single receiver, which imports all measurement data into the CAN J1939 network.

Optionally, the system can be expanded with a TPMS repeater. In most cases, the repeater is installed in the trailer. However, if the tractor is not equipped with its own QTIS tyre pressure control system, a receiver can also be mounted on the trailer and read out via ISOBUS on the in-cab display.

The advantage of the QTIS control architecture is that it offers maximum flexibility to expand your fleet with the QTIS tyre pressure control system, and that all vehicles automatically recognise each other once connected.

If you prefer to supply your own ECU and develop your own software, but still wish to use the TPMS sensors, you can request the CAN J1939 import code here: e-mail

The operating system

There are two main challenges for the control system: connecting and controlling all the components that are spread out on the vehicle, and easily setting the tyre pressures via your in-cab screen.

Every vehicle equipped with a QTIS tyre pressure control system is fitted with an ECU control module, connected to the CAN J1939 bus system and running ISOBUS software, tested and approved by the AEF.

The ECU can autonomously perform all tasks, including compressed air conditioning and setting the tyre pressures. Vehicles are interconnected via the ISOBUS connector to the in-cab display (VT – Virtual Terminal). Tyre pressure is monitored by modified TPMS sensors, which wirelessly transmit the tyre pressure to the TPMS receiver (optionally via a TPMS repeater). The receiver forwards the values to the ECU on the vehicle via the CAN J1939 protocol.

The software is designed to treat all connected vehicles as a single integrated system, with clear visualisation and control via your in-cab display. The core principle behind the software is that you can continue using your own sensors for pressure, dew point, and inclination, eliminating the need for validating new sensors. The system provides software-based checks and warnings to support safety and reduce operational costs.

For OEMs, we can easily customise the software to match your control system or corporate branding. There is no need to make different choices based on cost considerations. However, if you prefer to use your own ECU and software, you can request the CAN bus import code for the TPMS sensors from us.

We're here to help you, and your customers.

Generation of compressed air: the compressor

To inflate your tyres quickly and minimise downtime in the field, a high-capacity compressed air compressor is recommended. Vane compressors and screw compressors are commonly used for tyre inflation. Due to short compressor cycles, moisture can build up in the oil, potentially impairing compressor performance. It is best to heat up the compressor oil thoroughly at least once every 3 to 5 operating hours by running the compressor for a minimum of 15 minutes, allowing the moisture to evaporate from the oil.

Although there are several options for drying the compressed air (cooling, adsorption and membrane drying), sufficient attention is rarely paid to this. But we all know the consequences of damage caused by moisture in your air system: corrosion, clumped dirt, stuck components due to disturbed lubrication, water hammer, frost damage and more.

A few examples of what one inflation cycle of your tractor with trailer (5000 litres tyre volume and two bar pressure increase) can generate in condensation under different conditions: (see table below)

| Temperature | Grams vapour/ m3 |

|---|---|

| 7 °C | 7.73 |

| 6 °C | 7.25 |

| 5 °C | 6.79 |

| 4 °C | 6.36 |

| 3 °C | 5.95 |

| 2 °C | 5.57 |

| 1 °C | 5.21 |

| 0 °C | 4.87 |

| Temperature | Grams vapour/ m3 |

|---|---|

| 40 °C | 50.67 |

| 35 °C | 39.29 |

| 30 °C | 30.08 |

| 25 °C | 22.83 |

| 20 °C | 17.15 |

| 15 °C | 12.74 |

| 10 °C | 9.36 |

| 8 °C | 8.24 |

Dry spring day: 20°C, relative humidity 35% and 1m3 of air contains: 0,35%*17,5g/m3= 6.1 grams of water vapour. At 10 bar of compressed air, 11 m3 is compressed with 67.4 grams of compressed water vapour. After cooling to 20°C, 17.5 grams of water vapor will remain in the air and 67.4-17.5 = 49,9 grams of condensate is made by 1000 litres of air at 10 bar.

Humid summer day: 35°C, relative humidity 55% and 1m3 contains 0.55 * 39.29 gr/m3 = 21.61 grams. At 10 bar and after cooling: (11 x 21.61) – 39.29 = 198,41 grams of condensate is made by 1000 litres of air at 10 bar.

Crisp winter's day: 0°C, relative humidity 15% and 1m3 contains 0.15% *4.87 gr/m3= 0.73 grams of water vapour. At 10 bar and after cooling: (11 x 0.73) – 4.87 = 3,16 grams of condensate is made by 1000 litres of air at 10 bar.

Filter and dry compressed air

Although the compressor's intake filter can remove dirt and dust, water vapour from the ambient air is still drawn in and mixed into the compressed air. Since warm air exiting the compressor can hold more water vapour than cold air, the vapour will eventually reach a saturation point (dew point) somewhere in your compressed air system as it cools, at which point it condenses into water. As long as the compressed air continues to cool, it will keep releasing condensate.

This is why cooling air in storage tanks releases condensate. However, when inflating tyres, the warm compressed air flows throughout the system, and without proper measures, condensation can occur almost anywhere. Our advice: cool the compressed air as much as possible and remove the resulting condensate using a cyclone filter and a condensate drain. Optionally, use a large adsorption dryer to further dry the air, ensuring no damage occurs even in freezing conditions.

Reach out for bespoke advice.. Of course, we can also integrate your existing compressor into the optimal control system to provide the best technical solution.

The QTIS tyre pressure control system

We understand that you may not wish to change the compressor on your vehicles after all these years, or that you prefer to use your own ECU to avoid validation procedures. However, the tyre pressure control system is the minimum QTIS solution you can implement. A rim valve is mounted on the wheel and connected via a single Ø16 mm supply line to the rotary union, which is centrally installed on or inside the axle and linked to the valve block. The rim valve maintains tyre pressure while the hose normally remains pressure-free.

When the valve block supplies a pressure of up to 4 bar to the supply line connected to the rim valve, the tyre is inflated. Once the target pressure is reached, the valve block vents the supply line. If you want to deflate the tyre, the control system switches the valve block to a high-pressure mode (> 7 bar), causing the rim valve to shift to a deflation position. The contaminated air from the tyre passes through a fine, large-surface filter inside the rim valve and is vented directly into the atmosphere, preventing contamination of your system’s air supply.

We recommend that your supply line has a minimum internal diameter of Ø12 mm. This ensures that the deflation capacity of our rim valve is the fastest on the market, achieving 0.05 bar/sec with a 900-litre tyre. The smaller the tyre, the faster the deflation.

To reduce tyre inflation times, you can also work with higher inflation pressures — but this requires using higher deflation pressures as well. For this purpose, we recommend adding an extra pressure tank of approximately 20 litres per vehicle.

Please note: inflation times always depend on the compressor capacity, as well as the volume and pressure of the compressed air tanks. For product details and STEP files of the valve block, rotary unions and rim valve, see QTIS PARTS.

We are happy to provide a test installation on your vehicle, offer design support, or prepare a technical proposal for the complete system.

TPMS sensors

We have chosen TPMS (Tyre Pressure Monitoring System) sensors, mounted directly onto the standard TR618A valve in your rim. This method ensures the most reliable pressure measurement. Installation inside the tyre is also possible.

When measuring pressure in flowing air lines, you are dealing with dynamic pressure, which can show significant deviations compared to the static pressure present inside the tyre. Therefore, if you want to set tyre pressures quickly and accurately, we recommend measuring directly inside the tyre. This allows you, for example, to detect leakage or unwanted tyre heating, or to adjust the pressure on one side of the vehicle in sloped conditions.

We have improved the tyre pressure sensor with faster pressure feedback for a more accurate system. The TPMS sensors wirelessly transmit the tyre pressure, temperature, and battery status from each tyre to a single receiver, which imports all measurement data into the CAN J1939 network.

Optionally, the system can be expanded with a TPMS repeater. In most cases, the repeater is installed in the trailer. However, if the tractor is not equipped with its own QTIS tyre pressure control system, a receiver can also be mounted on the trailer and read out via ISOBUS on the in-cab display.

The advantage of the QTIS control architecture is that it offers maximum flexibility to expand your fleet with the QTIS tyre pressure control system, and that all vehicles automatically recognise each other once connected.

If you prefer to supply your own ECU and develop your own software, but still wish to use the TPMS sensors, you can request the CAN J1939 import code here: e-mail

The operating system