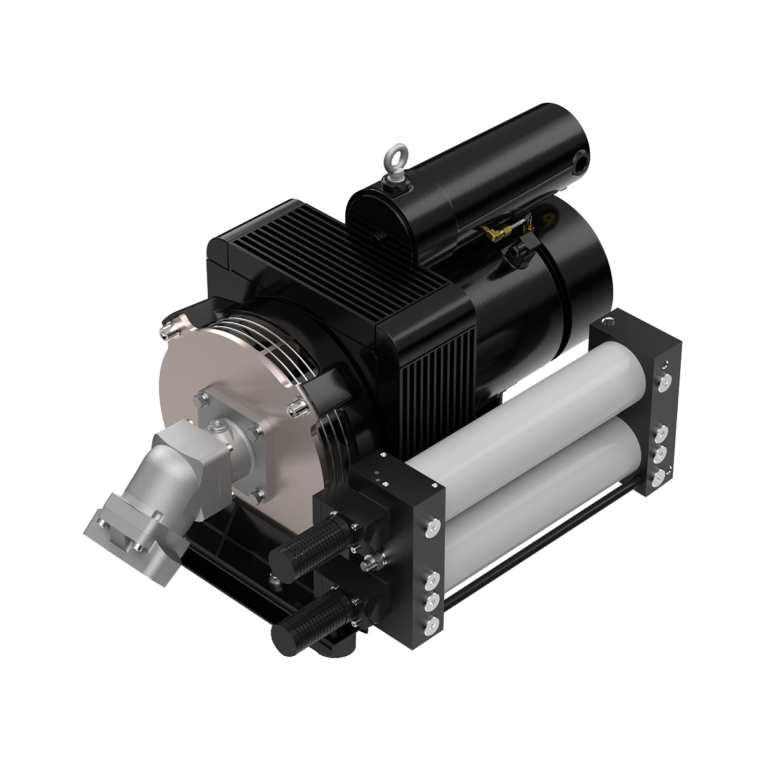

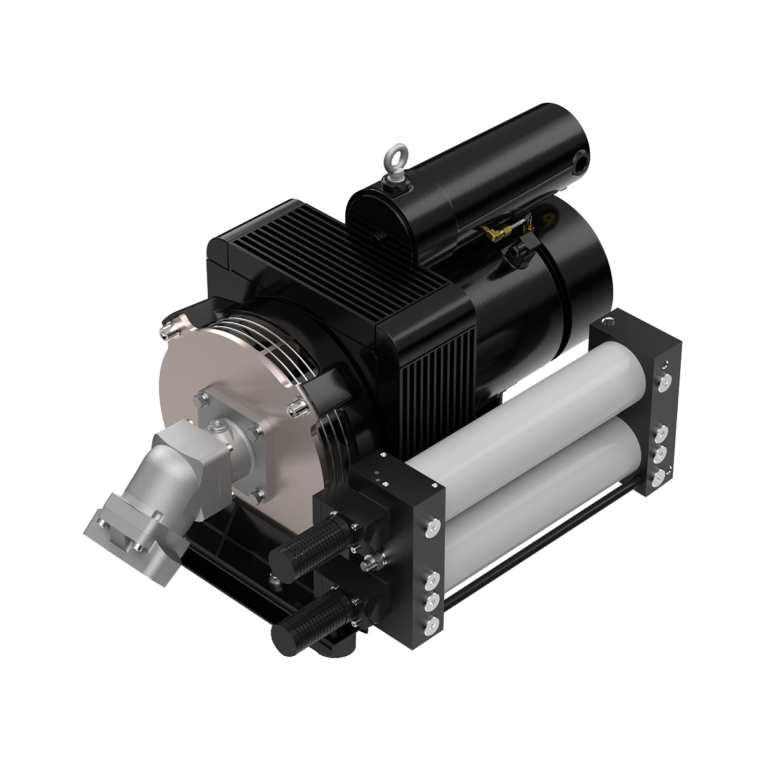

GENERATE EN DRY COMPRESSED AIR

In order to fill the tyres quickly and to keep waiting times in the field as short as possible, a high-capacity compressed air compressor is required. For compressed air production, vane compressors and screw compressors are mainly used. Due to the short compressor cycles, the oil suffers condensation damage that can impair compressor operation. We have included software in the QTIS control that maintains the oil quality.

Generate en dry compressed air

In order to fill the tyres quickly and to keep waiting times in the field as short as possible, a high-capacity compressed air compressor is required. For compressed air production, vane compressors and screw compressors are mainly used. Due to the short compressor cycles, the oil suffers condensation damage that can impair compressor operation. We have included software in the QTIS control that maintains the oil quality.