QTIS TYRE PRESSURE CONTROL SYSTEM

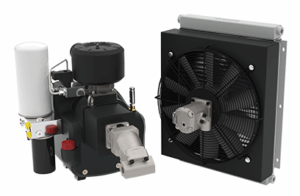

Compressed air conditioning

Inflating times of your tyres are determined by your compressor capacity; compressed air drying prevents downtime.

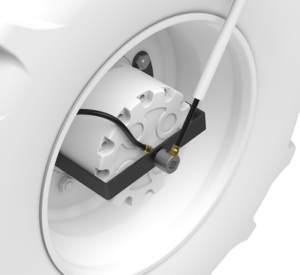

Rotary joints for mounting over the mudguard

QTIS rotary joints for tractors and trailers, corrosion-resistant and long-life.

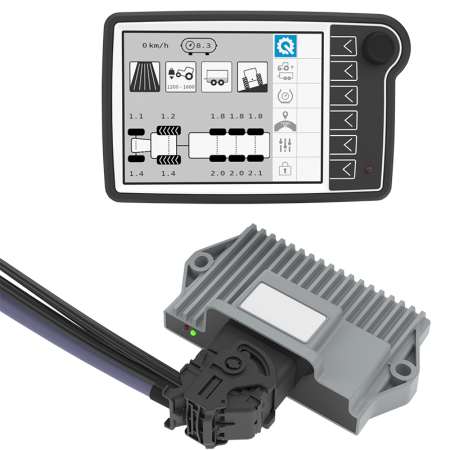

Electronic Control Unit

QTIS offers two models of ECUs to suit your cabling system. CAN, ISOBUS, AEF and very affordably priced.

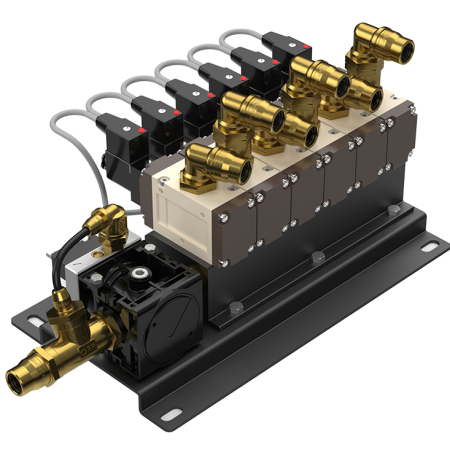

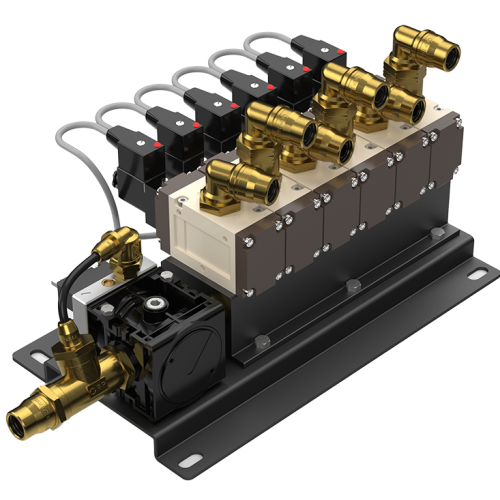

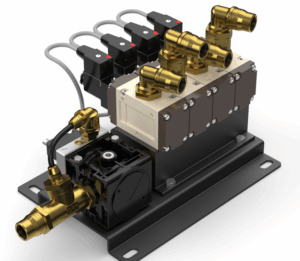

Valve manifold

The compact QTIS 4- or 6-way valve manifold to inflate and deflate your tyres with a single line.

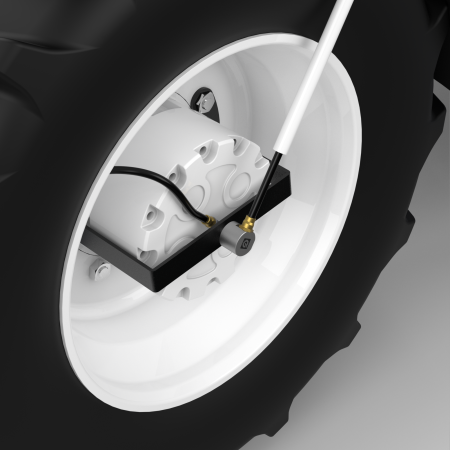

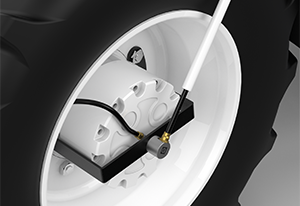

Wheel valve

Only one line with a large flow for all functions. Very fast deflation, filtered tyre air directly to the open air.

Accessories

Cable sets, fittings, filters, hoses, tanks or water separators. The service products you're probably familiar with.

Rotary joints for mounting in bored axles

QTIS rotary joints for trailers, corrosion-resistant and with long service life.

TPMS

Wireless tyre pressure sensors to quickly measure, present, and adjust the correct tyre pressures.

QTIS TYRE PRESSURE CONTROL SYSTEM

Why you need a tyre pressure control system?

Tyre replacement and fuel consumption are two major cost items in your agricultural operations. So you need all your farmland to cover these costs with good harvests. A Central Tyre Inflation System (CTIS) provides cost savings, increased safety and increased productivity. Climate change has greatly increased the risk of long wet periods. The QTIS® tyre pressure control system will help you to work the fields under all conditions. In fact, the system pays for itself. Reliable, smart and affordable!

- Less tyre wear, more effective field hours

- Longer field season, less downtime and breakdowns

- Less soil compaction, higher yields

- More grip, more effective pulling power

- Reduced fuel consumption, in the field and on the road

- Quick tyre pressure change, less waiting times

- Better vehicle control, handling and braking

Why you need a QTIS Tyre Inflation System?

We didn't take any chances when redeveloping our QTIS tyre pressure control system. The design requirements are based on our many years of experience, consultation with our customers and with users of other brands in the market. In this way, we challenged ourselves by including all the requested improvements in a redesign. We have now realized the following design requirements for you:

- Suitable for tractors, self-propelled and trailers, with tyre pressures up to 6.5bar and up to 1800 l/min FAD filling speed per tyre. (compressor dependent).

- Modular construction, choose the components you need and use your own knowledge and components where you can.

- ISOBUS control with easy adjustment of tyre pressures depending sub-soil, loads and terrain slopes.

- One tubing for three pressures. Default pressureless, 4 bar for inflating and 7 bar for deflating the tyres.

- No damage risk in the case of run-off hoses. Tyres are sealed off.

- No polluted tyre air back into the clean compressed air system. Tyre air is filtered before blowing off directly to the outside.

- Correct pressure measurement in the tyre in order to prevent pressure differences between flowing air in the supply line and the actual tyre pressure.

- Large bores for the best deflating times in the market, and for maximum utilization of compressor capacity when increasing tyre pressure.

- Software warning for leaks, tyre overheating, high speed at low tyre pressure, compressor management, among other things.

- Robust and corrosion-resistant materials and products, disassembleable, cleanable, repairable.

- Quick and easy installation, suitable for serial installation.

- OEM based production methods.

Why you need a tyre pressure control system?

Tyre replacement and fuel consumption are two major cost items in your agricultural operations. So you need all your farmland to cover these costs with good harvests. A Central Tyre Inflation System (CTIS) provides cost savings, increased safety and increased productivity. Climate change has greatly increased the risk of long wet periods. The QTIS® tyre pressure control system will help you to work the fields under all conditions. In fact, the system pays for itself. Reliable, smart and affordable!

- Less tyre wear, more effective field hours

- Longer field season, less downtime and breakdowns

- Less soil compaction, higher yields

- More grip, more effective pulling power

- Reduced fuel consumption, in the field and on the road

- Quick tyre pressure change, less waiting times

- Better vehicle control, handling and braking

Why you need a QTIS Tyre Inflation System?

We didn't take any chances when redeveloping our QTIS tyre pressure control system. The design requirements are based on our many years of experience, consultation with our customers and with users of other brands in the market. In this way, we challenged ourselves by including all the requested improvements in a redesign. We have now realized the following design requirements for you:

- Suitable for tractors, self-propelled and trailers, with tyre pressures up to 6.5bar and up to 1800 l/min FAD filling speed per tyre. (compressor dependent).

- Modular construction, choose the components you need and use your own knowledge and components where you can.

- ISOBUS control with easy adjustment of tyre pressures depending sub-soil, loads and terrain slopes.

- One tubing for three pressures. Default pressureless, 4 bar for inflating and 7 bar for deflating the tyres.

- No damage risk in the case of run-off hoses. Tyres are sealed off.

- No polluted tyre air back into the clean compressed air system. Tyre air is filtered before blowing off directly to the outside.

- Correct pressure measurement in the tyre in order to prevent pressure differences between flowing air in the supply line and the actual tyre pressure.

- Large bores for the best deflating times in the market, and for maximum utilization of compressor capacity when increasing tyre pressure.

- Software warning for leaks, tyre overheating, high speed at low tyre pressure, compressor management, among other things.

- Robust and corrosion-resistant materials and products, disassembleable, cleanable, repairable.

- Quick and easy installation, suitable for serial installation.

- OEM based production methods.